Machinery

Film Wrapping Systems

At Marden Edwards, we design, manufacture and supply high-performance carton ovewrapping systems for a wide range of industries. With more than 10,000+ machines installed across 150+ countries, we are trusted worldwide for our expertise in Point of Sale and Distribution packaging.

Our range of overwrapping machines are built for consistency, reliability, and clean, professional finish - regardless of your production volume or product format. Each overwrapping system is developed by our experienced team to suit your packaging requirements, ensuring smooth integration into your production line.

Whether you are wrapping perfume cartons, pharmaceutical boxes or multipack bundles, Marden Edwards provides equipment that's built to last, easy to operate, and backed by decades of industry knowledge.

Contact us today to find out how Marden Edwards can support you in the packaging operations.

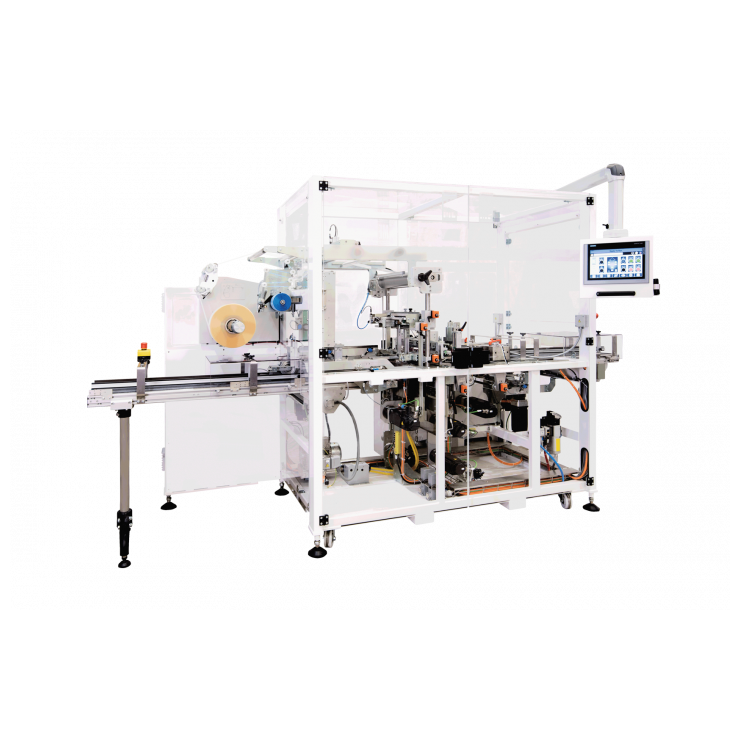

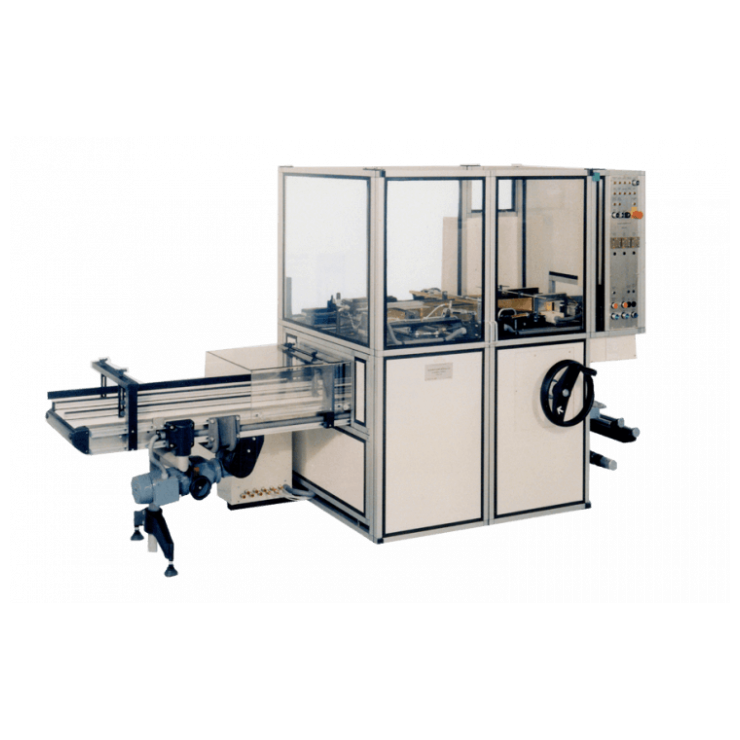

Overwrapping Machinery

A pack wrapping machine solution which automates the hand wrapping process whilst producing geometrically exact envelope style end folds.

Shrinkwrapping Machinery

We supply a complete range of shrink wrapping machines including chamber machines, l-sealers, sleeve wrappers and sealers, heat shrink tunnels, and shrink wrapping materials.

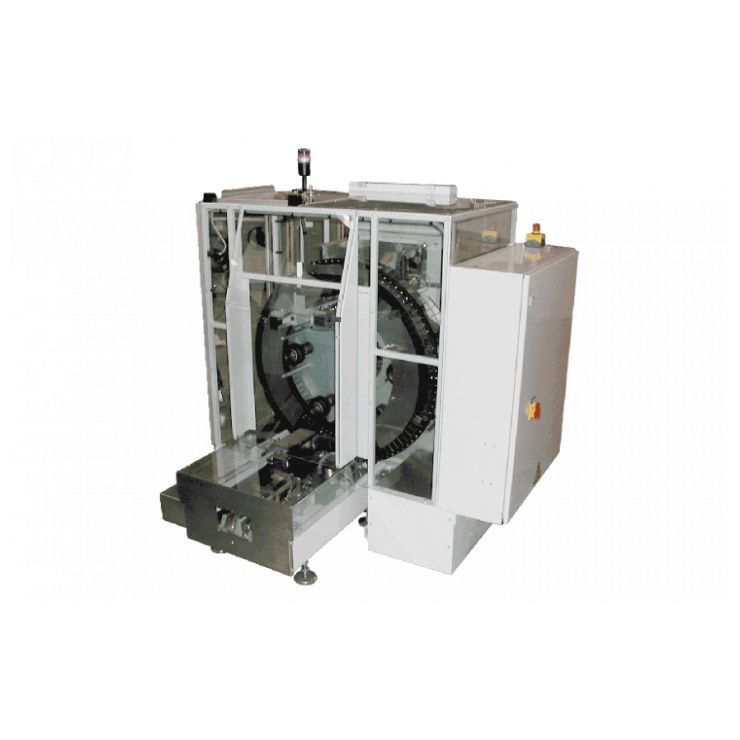

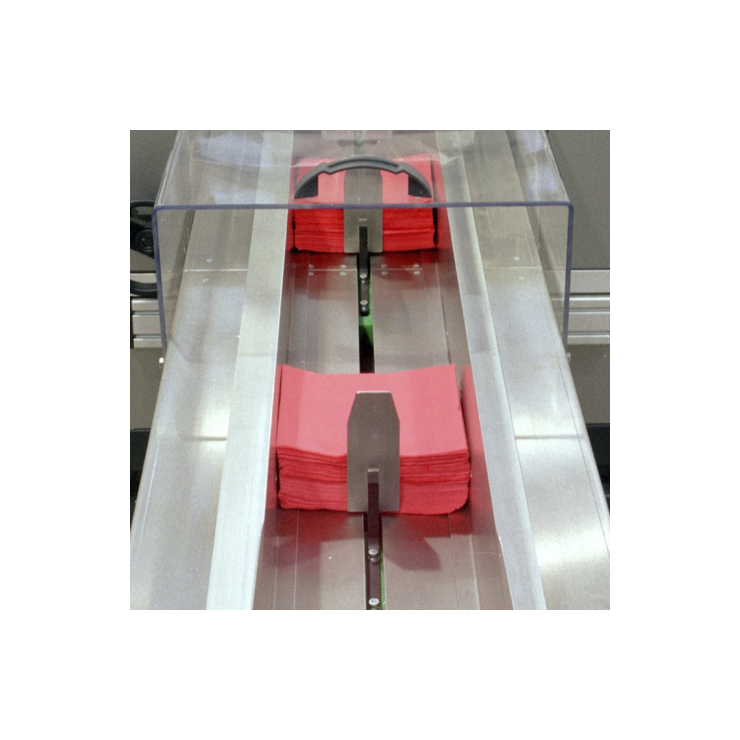

Banding Machinery

The ABS series banding machine range incorporates diverse product handling and utilises a banding head that can operate with either BOPP or paper material.

Approved Used Machinery

Factory reconditioned at our UK facility, our refurbished wrapping machines come with comprehensive service support and warranty.

Custom Packaging Machinery

Marden Edwards can custom design a packaging machine to your precise application requirements.

Product Handling Systems

Marden Edwards design and build bespoke equipment to accommodate a variety of product needs.

English

English

Deutsch

Deutsch Español

Español Français

Français Русский

Русский USA

USA